History

“Power by the Hour” or PBH was invented by British engine manufacturer, Rolls-Royce, in 1962 to support the Viper engine on the Havilland/Hawker Siddeley 125 business jet. The agreement between the engine OEM and engine operator promises a complete engine and accessory replacement service subject to a fixed-cost-per-flying-hour basis. In other words, the agreement is designed to shift the financial burden and risk of engine maintenance from the operator to the OEM. As a result, operators remove risk related to unscheduled maintenance events and make maintenance costs planned and predictable. Engine OEMs also like this agreement because if the engine operates to expectation, they receive a steady stream of cash flows upfront, which have historically escalated at a high single digit to low double digit rate annually.

Long-Term Operating Model

Engine OEMs invest for the long term and do not operate quarter-to-quarter. The typical development cost for a new engine such as General Electric’s LEAP or Pratt & Whitney’s GTF is $10bn. The companies undertake short-term losses in order to get new engines on wings (Razor Blade Model). This is critical because the time to service these engines could be over forty years. During this period, OEMs generate many multiples of profits servicing the engine versus the cost of manufacturing the engine. Below is an example of how OEMs deliver loss-generating engines in the near term to reap the benefits of the parts and services sales over the long term.

Cash Cost

Engine OEMs are paid by customers through long-term service agreements, which are typically ~10 years in duration depending on the engine. The payment structure works exactly as it reads.

- Every flight hour the engine is utilized, the OEM gets paid cash from the aircraft operator. For context, OEMs book revenue on the income statement only after service costs are incurred to repair an engine during a shop visit.

- Importantly, OEMs estimate the contract margin in order to anticipate the remaining costs and associated revenues on the contract. This projection is based on the number and historical cost of a shop visit, as well as the agreed usage of expected flying hours and the rate per hour. In the example below, the OEM assumes a 50% contract margin rate.

- Over the life of a PBH contract, cash and profit must equal one another.

- In any given year, for a single PBH contract, cash flows and profits will almost never be equal.

- The difference between cash revenues and GAAP revenues goes to the balance sheet as “net LTSA liability.”

- Over time, profit equals cash and the LTSA balance ends at zero.

- In many cases, it can be years between receiving cash payment versus recognizing the engine service cost.

In an ideal scenario, OEMs would have the engines function on the aircraft wing indefinitely, and thus assume no shop visit costs. Below we highlight an example of a Power by the Hour contract with stable cash receipts and one major shop visit in year five. Additionally, the impact on each of the three financial statements is indicated.

Impact on Cash Flow

Power by the Hour has attractive cash flow generation characteristics that are annuity-like in nature and can grow HSD to low DD annually. Additionally, there are escalators that take into account inflation. Furthermore, OEMs can “unbundle” life limited parts (spare parts) and charge highly attractive margins which are not covered under the standard Power by the Hour contract. Below we highlight an example of an engine that incurs a shop visit in year five and ten. Approximately two-thirds of total costs are incurred during the shop visits while the remaining one-third accrues evenly each year. As seen in Exhibit 2, the contract cash flow is positive every year except for those where there is a major shop visit. Notably, cash inflows are received from the first year onward. It is worth noting if engine OEMs are able to drive down the cost to do a shop visit, the cash flow margin for the engine increases.

Win-Win for Airlines and OEMs

Power by the Hour is a risk-sharing model. This benefits the airlines operating the engine since they only pay when the engine functions. Conversely, a positive aspect of the model for OEMs is they receive cash payments upfront, before incurring any costs related to engine maintenance. In summary, incentives are aligned for the engine to function. Additional benefits include a clearer line of sight into future costs for airlines and OEMs. Below we list out the main advantages for both airlines and OEMs.

Unit Economics

The engine is the most important system on the aircraft. As such, the cost of the engine is approximately 15% of the total aircraft value. For example, the list price for a 737 MAX-8 is ~$122m. Therefore, the engines would be $18.3m together or $9.15m individually. There is a 50% markdown to make the aircraft more affordable. This means the initial sale of the engine is at a negative margin to the OEM. However, as mentioned, the OEMs benefit from the high value of the Power by the Hour contract for the life of the engine. Below is an illustrative example of how the unit economics work for the 737 MAX-8, along with other aircraft types.

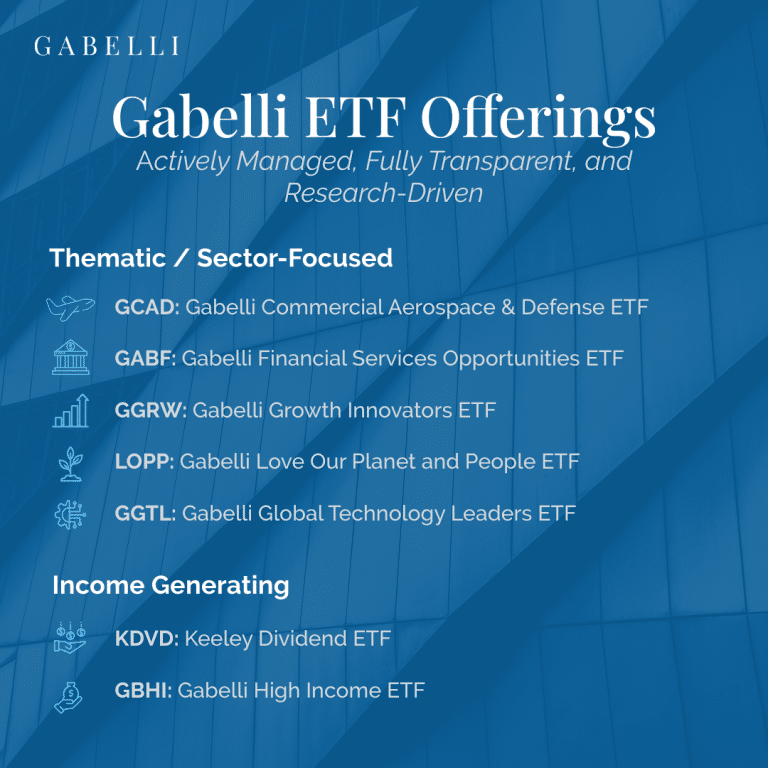

Investment Opportunities

To summarize, Power by the Hour creates an attractive annuity-like cash flow for the engine manufacturer. Additionally, cash flow is tied to flight hours, which have historically grown at a rate in excess of GDP. Further, OEMs have the benefit of setting annual price increases in excess of inflation, which can be in the HSD to low DD range.

Michael Burgio

(914)921-7797

Mburgio@gabelli.com Gabelli Funds 2024

ONE CORPORATE CENTER RYE, NY 10580 Gabelli Funds TEL (914) 921-5000